Small but oh boy! Heat sink solutions for printed circuit boards

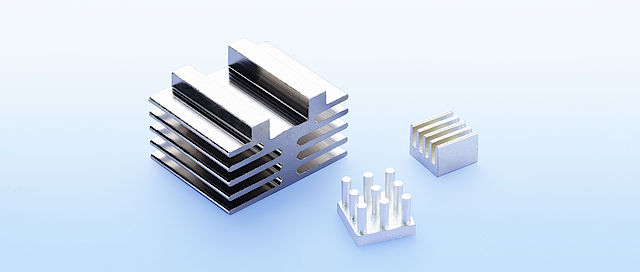

PCB heat sinks cool specific high-power electronic components, singly or in groups. Our wide-ranging portfolio of standard heat sinks for PCB cooling comprises several hundred different models with Rth values between 6 and 72 °C/W. These include, for example:

- Clip-on heat sinks for semiconductor housing types TO-220 and TO-218

- Extruded SMD heat sinks

- Stamped low-profile heat sinks for standard D-PAK (TO-252), D²PAK (TO-263) and D³PAK (TO-268) modules

- Profile heat sinks with integrated soldering pins for wave soldering on the PCB

- Soldered, clip-on or screw-on heat sinks

In addition to standard versions, every type of heat sink is also available as a project-specific version.

Always the optimal cooling solution for your PCB

Our board level heat sinks are made of aluminum or copper, optionally using sheet bending, extrusion or die-cast technology. Which heat sink is the optimal solution for your application depends on the particular cooling capacity requirements and the installation space, the number of heat sinks required and the method for mounting the heat sink.

Various mounting types

Whether the heat sink is fastened to the PCB by means of clips, rivets, soldering pins or screws depends on the type of heat sink, the application and the required quantity.

In the case of large quantities, mounting clips reduce high-labor activities. They are the preferred mounting type for extruded PCB and clip-on heat sinks. Finger heat sinks are typically equipped with integrated soldering lugs during production. Other heat sink variants can also be mounted directly on the PCB by means of soldering pins.

However, if the PCB and heat sink are subjected to vibrations or shocks, such as in railway technology, screws provide the most reliable connection. Another advantage of this mounting type: It can easily be removed for servicing.

Our clip and spring solutions

- Standard clips and brackets

- Project-specific stamped and formed sheet metal parts

- Flat springs

- Wire bending parts

- Compression springs, tension, torsion and micro springs

The advantages of our clip and spring solutions at a glance

- Reliable connection

- Effective heat transfer

- Simplified insulation capabilities

- Excellent fracture strength

- Complex geometries are possible

- Very good cost-effectiveness ratio

- Top-quality raw material from certified manufacturers

- Guaranteed traceability

- In-house hardening

- Quality inspections during and after production

Talk to us

CONTACT