When space is at a minimum Heat pipe cooling systems for efficient heat transfer

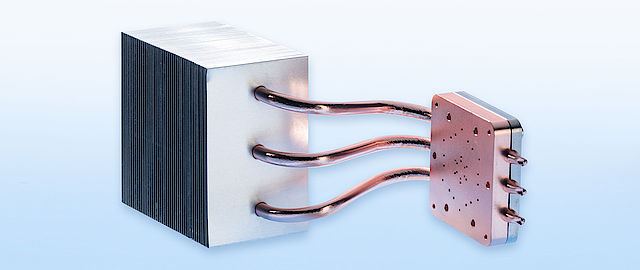

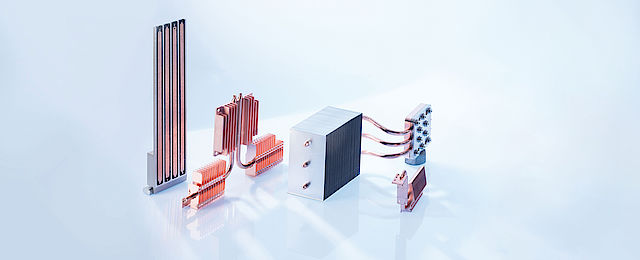

Cooling systems consisting of a heat sink and heat pipes feature excellent heat dissipation even over large distances. The copper heat pipes transfer the heat from the electronic component to a heat sink, which then dissipates the heat into the ambient air. In the case of very high heat generation the heat pipe system can also be combined with a fan for forced cooling.

Here you can download our image brochure with one click

How it works

A heat pipe – generally a copper pipe with an internal capillary structure of sintered copper wire mesh – is a closed system with a coolant in a vacuum, which uses the phase change between evaporation and condensation of the liquid for heat transfer. The coolant (methanol or water) evaporates in the hot zone of the heat pipe, releasing evaporation heat and lowering the pressure in the pipe. As a result of the pressure differential the vapor flows to the cold zone of the heat pipe at the transition to the heat sink and condenses there, giving off condensation heat. Due to the capillary effect generated by the capillary structure in the heat pipe or by gravity, the liquid flows back into the hot zone. The circuit starts anew. In this way, heat pipes dissipate high amounts of heat despite minimal temperature differences. That makes them the most efficient heat exchangers.

The advantages of heat pipe systems

Heat pipes can be combined with many different types of heat sinks to meet individual requirements. The cooling capacity of the systems can be improved many times over by increasing the number of heat pipes and/or by combining the system with a fan. Since heat pipe cooling systems operate independently and need no external water pumps or pipes, they also require less maintenance than liquid cooled systems. Other benefits:

- High cooling capacity

- Robust, low-maintenance cooling solution

- Even temperature distribution

- Can be installed virtually anywhere

- High freedom of design due to easy workability of heat pipes

- Relatively low thermal resistance

- Ideal for tight installation situations

- Excellent thermal conductivity also over long distances

Typical applications of heat pipe systems

Heat pipe cooling systems are used wherever the installation conditions prevent the heat sink from being connected directly to the electronic component. This applies for example to

- Notebooks

- CPUs

- Graphic adapters

- LED modules

- Processors

- Press-pack components

- IGBTs

- SiC components

- Electronic components in (electric) vehicles

Heat pipe systems are also the preferred cooling solution in satellites and space travel.

Heat pipe cooling systems from CTX: All from a single source

Whether you need a single heat pipe assembly, entire sets or turnkey custom-designed heat pipe cooling systems – we deliver exactly what you need.

We will be glad to assist you in the design of the cooling solution and, on request, will also develop the application-specific heat pipe system as well as the mechanical machining (CNC) and surface finishing.

Our services likewise include prototyping, functional checks, and the design of attachments and packaging for the specific application.

Talk to us

CONTACT