LED heat sinks from CTX Effective cooling and a convincing design

Energy-efficient, eco-friendly and long-lasting LEDs are the most common type of light source nowadays. They illuminate boutiques, food stores, hotels, ships, office buildings, churches, museums, cars, streets, buses and trains, and many other areas of daily life.

And although LEDs are much more efficient than conventional light bulbs, light emitting diodes likewise convert 75 to 85 percent of the power input into heat, depending on the color and luminous intensity. This heat is dissipated from the barrier layer through the metal connections to the PCB and from there into the environment. The temperature at the barrier layer also affects the dominating wavelength and brightness of the LED and therefore the color of the light. The brightness of the lamp therefore decreases as the temperature rises, and the color also changes. Effective thermal management with LED heat sinks designed for the particular application is therefore essential for ensuring consistent luminous efficiency and color of the LED, as well as a long service life.

LED heat sinks Special heat sinks for special applications

Every application has different requirements for the type of LED and how it is cooled. In the case of small LED lights with a power consumption in the milliwatt range, the solder connections are sufficient to dissipate the heat from the semiconductor crystal. Power consumption of about one watt or more already necessitates the use of (passive) cooling. High-power light emitting diodes that operate with amperage of more than 20 milliamperes produce so much heat that they even require LED heat sinks with forced ventilation (active cooling).

We offer a suitable LED heat sink for every purpose – from the standard solution to custom engineered cooling systems for efficient cooling of high-power LEDs!

LED heat sinks for lighting of public spaces

A long life and long maintenance intervals are essential criteria for lighting in public facilities and street lights, or in buses and trains. High-performance passive LED heat sinks assure these properties by means of fast and reliable cooling. They also require very little maintenance.

LED heat sinks for shop lighting

The clear, undistorted representation of colors is imperative for the illumination of products. In the case of foods – especially perishables such as fruits and vegetables – it is essential that lights do not generate much heat. In both cases, efficient high-performance heat sinks ensure the desired result through fast dissipation of the LED power loss.

LED heat sinks for the automotive sector

High-performance, very compact and a heat sink design that is individually adaptable to the particular light model – that describes the heat sinks manufactured by CTX especially for the automotive sector.

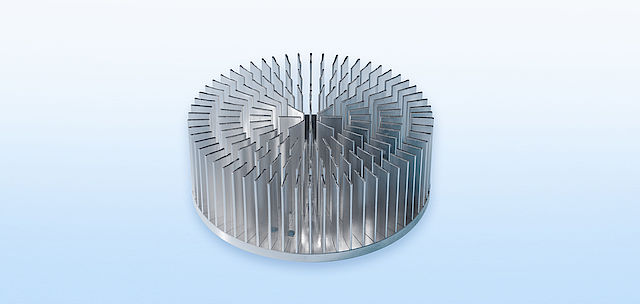

Optimal geometry for perfect cooling

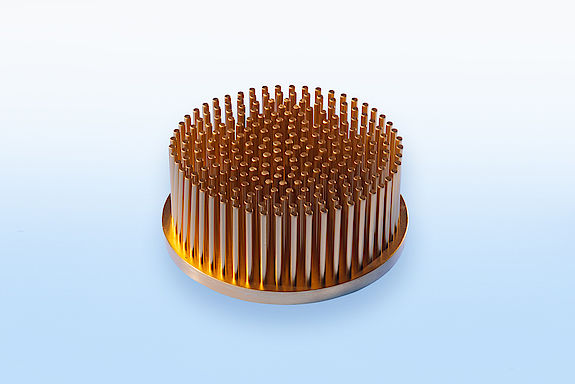

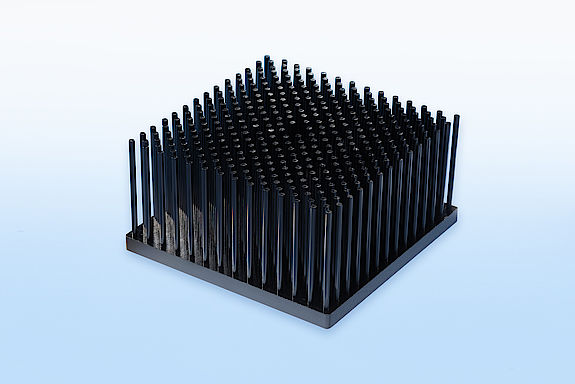

High-performance heat sinks for LEDs are generally pin fin heat sinks with an especially large surface area. In addition, a round or oval fin or pin shape ensures high air flow rates. The layout of the fins or pins also positively affects the air flow. The result is optimal cooling efficiency even with natural convection.

High-performance LED heat sinks: High performance in a compact design

In applications requiring dissipation of high heat in small or hard-to-reach areas – such as in motor vehicle construction – the use of cold extruded pin heat sinks of high-grade aluminum or copper is a good solution.

The advantages of cold extruded high-performance LED heat sinks are the large diversity of designs, high-precision shaping and, above all, excellent thermal conductivity. Due to the special material properties, their cooling capacity is about 30 % higher than that of extruded heat sinks and 40 % higher than die-cast heat sinks with the same dimensions.

LED heat sinks are mounted either by means of screws, clips, thermally conductive adhesive or brazing. They can also be combined with fans, if required.

The advantages of our LED high-performance heat sinks at a glance

- Diverse, complex geometries are possible: rotationally symmetric, angular, elliptical, eccentric

- Excellent thermal conductivity > 220 W/mK

- Fast and even heat dissipation over the entire heat sink

- Optimal cooling capacity with natural convection

- Small footprint

- Suitable for difficult installation situations

- Can be combined with a fan

Production process The design decides

Talk to us

CONTACT